The Basics

An English Wheel is a metalworking tool used for shaping and smoothing curved metal surfaces. It consists of a large, flat machine with two wheels, one stationary and one movable, which are pressed against the metal to gradually shape it into a desired form. The English Wheel is commonly used in automotive restoration and custom metal fabrication, particularly for creating curves in body panels and fenders. Skilled metalworkers can use an English Wheel to create nearly any shape, with the final result being a smooth, polished surface.

Photo Credit - Prestige Restoration - https://amyshorephotography.com/

What are the different types of Wheeling Machines? and what machines does Prestige Restoration have?

Prestige has 3 English wheels, all for different reasons and jobs.

Photo Credit - Prestige Restoration - https://amyshorephotography.com/

Where does it come from?

An English wheel comes from England, and its origins are tied to the rise of metalworking during the Industrial Revolution.

Here’s the background in plain terms:

The tool was developed in 19th-century England, where skilled craftsmen needed a way to smooth and shape thin sheet metal accurately.

It became especially important in coachbuilding—making carriage bodies—and later in early automobile and aircraft construction.

The name “English wheel” simply reflects where it was first widely used and refined, not that it’s exclusive to England.

Photo Credit - Prestige Restoration - https://amyshorephotography.com/

How to use an English Wheel?

Using an English wheel is about controlled stretching of sheet metal to create smooth curves. Here’s a clear, practical walkthrough.

What the English wheel does

It stretches metal by squeezing it between:

a large flat top wheel

a smaller curved lower anvil wheel

Stretching causes the metal to curve.

Basic steps

1. Choose the right metal

Mild steel, aluminum, or stainless

Common thickness: 18–22 gauge steel, .040–.063 aluminum

Softer metal is easier for beginners

2. Select the anvil wheel

Flatter anvil → gentler, larger curve

More crowned anvil → tighter curve

Start flatter than you think—you can always increase curvature later.

3. Set the pressure

Bring the wheels together until they just touch the metal

Add light pressure at first

Too much pressure = over-stretching and oil-canning

A good rule: you should feel resistance, not crushing force.

4. Wheel the metal

Move the sheet back and forth while gradually crossing your passes

Use a crisscross or overlapping pattern

Keep the metal moving—don’t dwell in one spot

Think of it like mowing a lawn: even, overlapping passes.

5. Check your shape often

Stop frequently and:

Sight down the panel

Use a contour gauge or template

Feel for highs and lows

It’s easier to add stretch than remove it.

6. Adjust as needed

More curve → slightly more pressure or a tighter anvil

Uneven areas → focus around the low spots, not directly on them

Key techniques

Stretching: Standard wheeling—creates curvature

Planishing: Very light pressure—smooths hammer marks

Edge control: Edges stretch faster; be careful near them

Common beginner mistakes

Using too much pressure too soon

Staying in one spot too long

Skipping around instead of using a pattern

Not annealing aluminum when it work-hardens

Photo Credit - Prestige Restoration - https://www.rwcphoto.com/

The Ranalah wheeling machine

A Ranalah English wheel refers to the Ranalah Company, one of the earliest and most influential manufacturers of English wheels, and it’s a big reason the tool became known as the English wheel in the first place.

Photo Credit - Prestige Restoration - https://amyshorephotography.com/

What did they use in Italy?

Yes — absolutely. 🇮🇹

The English wheel has been central to Italian car body construction, especially during the golden age of Italian coachbuilding.

Italian coachbuilders (carrozzieri) such as:

Pininfarina

Bertone

Touring Superleggera

Scaglietti

Vignale

used the English wheel extensively to form aluminum and steel body panels by hand.

Even though it’s called an English wheel, it became a standard European tool, not an English-only one.

How Italians used it differently

Italian craftsmen were famous for:

Very light wheeling pressure

Extensive use of wood bucks and templates

Combining the wheel with:

Hammer-and-dolly work

Shot bags

Gas welding

Shrinking techniques

This resulted in panels that were:

Thin

Strong

Exceptionally smooth

Aerodynamically refined

Photo Credit - Prestige Restoration - https://amyshorephotography.com/

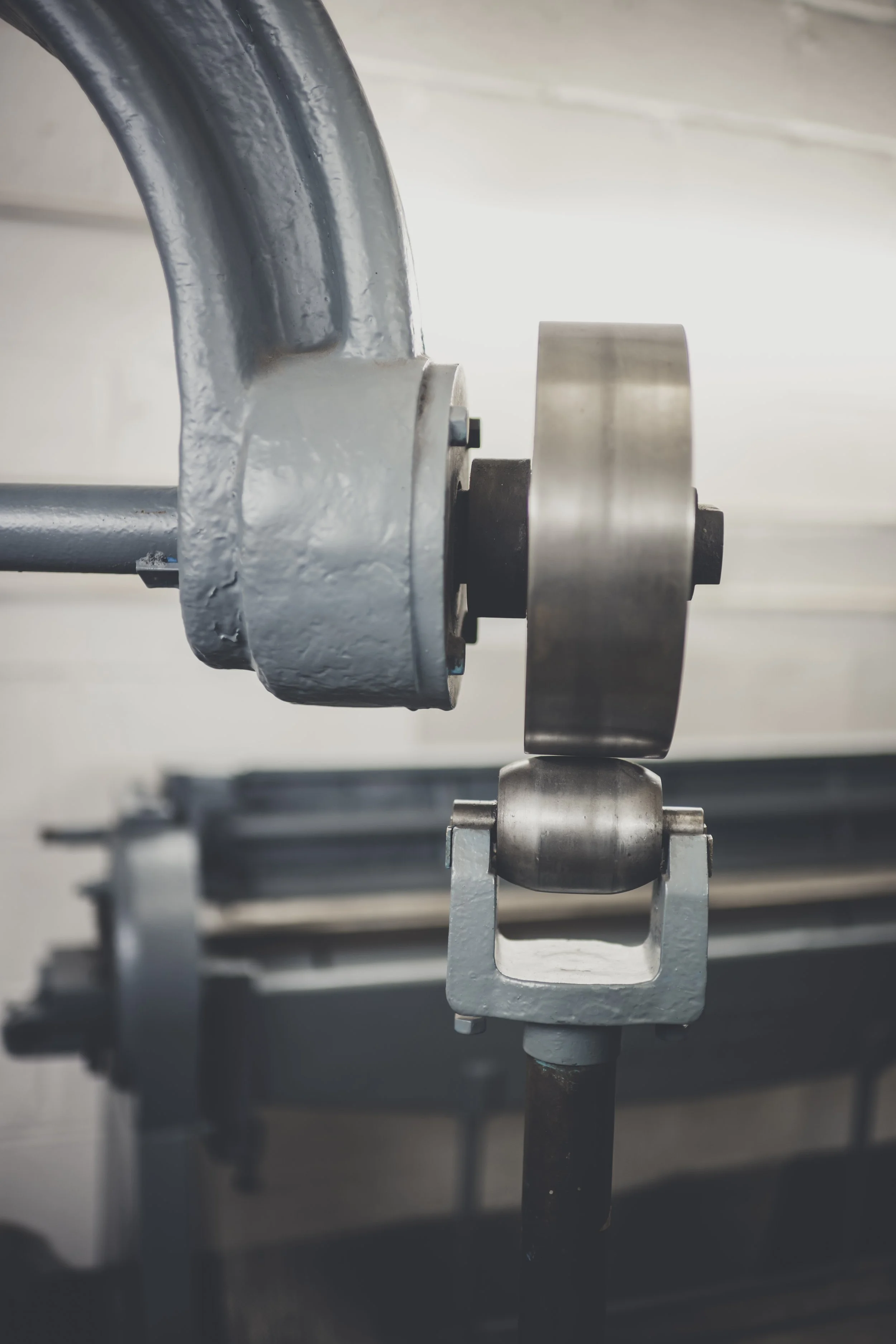

Why does it look like that?

The machine is shaped like a large, closed letter "C". At the ends of the C, there are two wheels. The wheel on the top is called the rolling wheel, while the wheel on the bottom is called the anvil wheel. (Some references refer to the wheels by their position: upper wheel and lower wheel.)

Photo Credit - Prestige Restoration - https://www.rwcphoto.com/

Photo Credit - Prestige Restoration - https://www.rwcphoto.com/

Photo Credit - Prestige Restoration - https://www.rwcphoto.com/